SQF Mock Audit Requirements

Daria Van De Grift

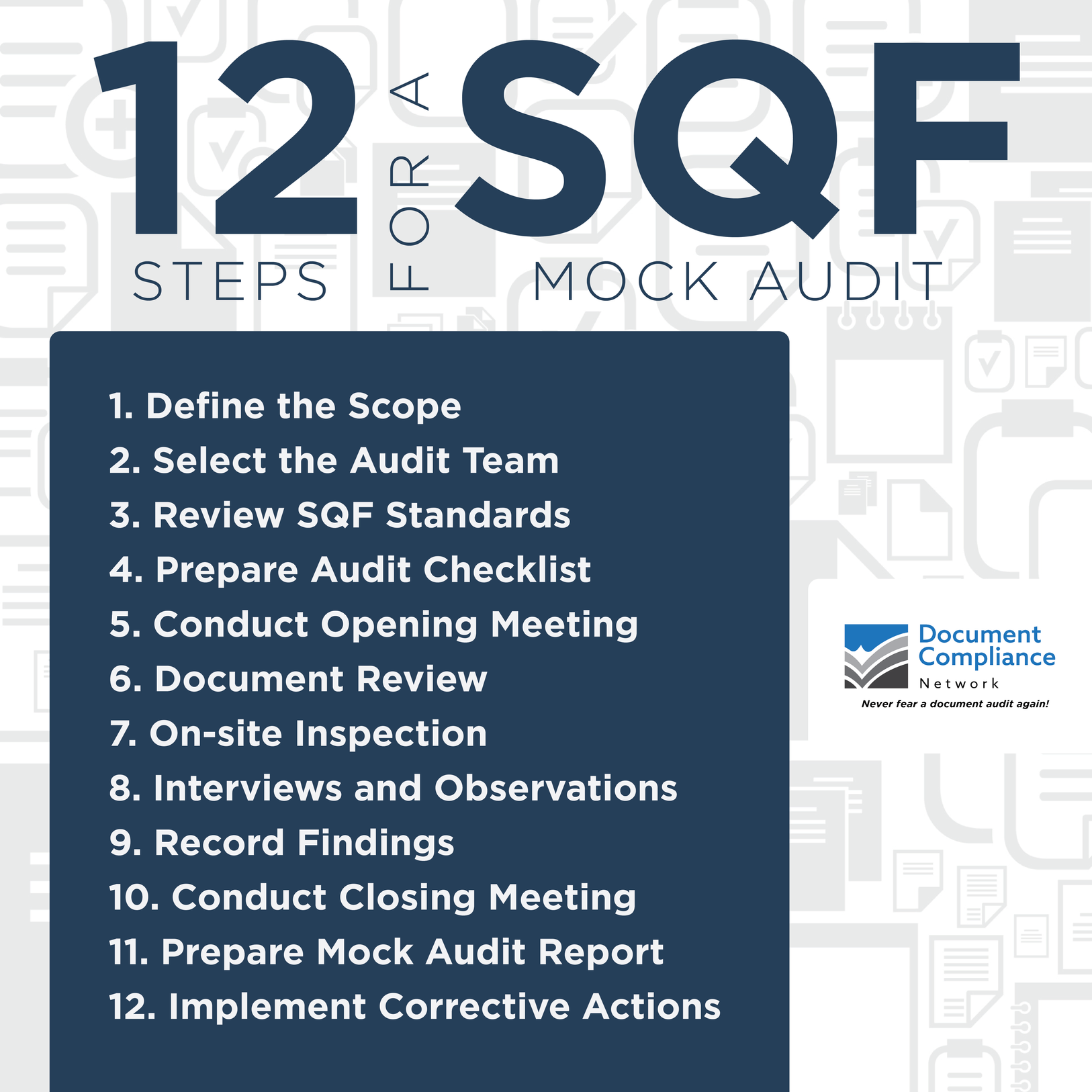

Performing a mock audit against the SQF (Safe Quality Food) standard involves simulating the audit process to assess your organization’s readiness for the actual audit. There are 12 steps in performing an SQF mock audit, these steps are; Define the Scope, Select the Audit Team, Review SQF Standards, Prepare Audit Checklist, Document Review, On-site Inspection, Interviews and Observations, Record Findings, Conduct Closing Meeting, Prepare Mock Audit Report, and Implement Corrective Action.

There are a lot of parts to conducting a mock audit as it is supposed to mirror what will happen when the certifier comes. Let’s take a look into each of the steps by defining the scope and then what activities will help you prepare for each step.

1. Define the Scope

Scope: Determine the specific scope of the mock audit, by specifying what parts of your company it will include. This could be specific lines or parts of the plant. What you choose to evaluate should encompass what your organization wants to have covered by the certification.

Activities:

-

Identify the specific production areas, processes, or facilities to be audited.

-

Determine the timeframe and duration of the mock audit.

-

Consider the key elements of the SQF standard that are applicable to your organization.

2. Select the Audit Team

Scope: Assemble a team who will conduct the mock audit. Your team should include both people with knowledge of the SQF standards and Ideally, the auditors should have knowledge and experience in SQF standards and auditing techniques. The team can consist of internal personnel or external consultants.

Activities:

-

Choose auditors with knowledge and experience in food safety management systems and SQF standards.

-

Provide training for each member on what parts of the SQF code they fall under.

-

Assign any specific roles and responsibilities to each member, such as lead auditor, documentation reviewer, or process validation.

3. Review SQF Standards

Scope: Review the SQF standard that your organization will be audited against. Understanding each section’s requirements, criteria, and what will satisfy that standard is important. Make sure that you are using the most recent version of the standard as they can have changed since the last audit.

Activities:

-

Go to the SQF website and download the new code and guidance materials.

-

Understand the requirements for each section, such as food safety fundamentals, hazard analysis, and management commitment.

-

Take note of any specific criteria that pertain to your facility that the auditors might focus on during the audit.

4. Prepare an Audit Checklist

Scope: Develop an audit checklist based on the requirements outlined in the SQF standard. The checklist should cover all relevant areas, such as management commitment, documentation, facilities, equipment, personnel practices, and food safety management systems.

Activities:

-

Develop a comprehensive checklist based on the requirements of the SQF standard. You can break up each standard into its own internal audit to be used regularly.

-

Use your audit team to each take a section of the standard to create a checklist for their area of operation.

-

Customize the checklist to align with your organization’s operations and processes. For example, having a checklist for receiving and then one for certain parts of the process.

5. Conduct an Opening Meeting

Scope: Start the mock audit with an opening meeting, similar to how it would be done in a real audit. Introduce the audit team, explain the purpose of the mock audit, and provide an overview of the audit process.

Activities:

-

Include everyone that will be asked to participate in the real audit; including who is the mock auditor, upper management, and key personnel that will be involved in the audit.

-

Introduce the purpose, scope, and objectives of the mock audit.

-

Establish the audit timeline and expectations to all participants.

6. Document Review:

Scope: Examine the organization’s documentation, including policies, procedures, records, and training documentation, to assess compliance with the SQF standard. Verify that the documentation is complete, up to date, and aligned with the requirements. This is made easier by having an electronic document system like Document Compliance Network.

Activities:

-

Review documented procedures, policies, and records related to food safety.

-

SQF has specific records requirements, so make sure that the documents specifically mentioned in the standard are up-to-date and correct.

-

Verify that records are up-to-date, accurate, and properly maintained.

7. On-site Inspection

Scope: Perform a comprehensive on-site inspection of the facilities, including production areas, storage areas, equipment, and sanitation practices. Evaluate the implementation of food safety measures throughout the plant.

Activities:

-

Perform a walkthrough of the production areas, storage facilities, and other relevant sections.

-

Assess the condition and cleanliness of the premises, including equipment, utensils, and infrastructure.

-

Evaluate compliance with food safety protocols, such as temperature control, sanitation, and hygiene practices.

8. Interviews and Observations

Scope: Conduct interviews with personnel to assess their understanding of and adherence to food safety practices. Observe employees carrying out their tasks to verify compliance with established procedures.

Activities:

-

Conduct interviews with employees at different levels, including managers, supervisors, and production workers.

-

Ask questions about their understanding of food safety procedures that pertain to their roles in the plant.

-

Observe employees as they perform their tasks, paying attention to their adherence to established processes and safety protocols.

9. Record Findings

Scope: Document any non-conformities, observations, or areas for improvement identified during the mock audit. Remember the more picky you are in the mock audit the better your real audit will be. Be clear and specific in describing the findings and reference the relevant sections of the SQF standard.

Activities:

-

Document any non-conformities, deficiencies, or areas for improvement found during the audit.

-

Categorize the findings based on the severity and urgency of corrective action needed so that you comply.

-

Support each finding with evidence, such as observations, records, or employee interviews.

10. Conduct a Closing Meeting

Scope: Conclude the mock audit with a closing meeting, similar to the one held in a real audit. Present the audit findings to the organization’s management. This includes any nonconformities that were found, as well as, a summary of your findings.

Activities:

-

Present the audit findings and observations to management.

-

Discuss strengths and commendable practices identified during the mock audit.

-

Provide recommendations for improvement and corrective actions needed to align with the SQF standard.

11. Prepare Mock Audit Report

Scope: Prepare a comprehensive mock audit report that outlines the findings, recommendations, and any corrective actions required. The report should be well-structured, clear, and concise, providing a clear direction for improving compliance with the SQF standard.

Activities:

-

Compile all the findings, observations, and recommendations into a comprehensive report.

-

Structure the report to include an executive summary, detailed findings, and recommended actions.

-

Include a clear timeline and responsible parties for implementing corrective actions.

12. Implement Corrective Actions:

Scope: Based on the findings and recommendations from the mock audit, develop and implement corrective actions to address any non-conformities or areas of improvement. Establish a timeline for completion and assign responsibilities to relevant personnel.

Activities:

-

Develop action plans to address each finding or non-conformity identified during the mock audit.

-

Assign responsibilities to appropriate individuals or departments.

-

Monitor the progress of corrective actions and ensure their completion within the specified timeline.

Remember that a mock audit is a valuable tool for assessing your organization’s readiness, identifying areas for improvement, and ensuring compliance with the SQF standard. Use the findings and recommendations from the mock audit to make necessary adjustments and enhancements to your food safety management system before the actual audit takes place. If you find any gaps as a result of the audit you have time to fix them before the real audit begins.

One of the biggest headaches that occurs is missing or expired documentation from your suppliers. You do not want to be caught scrambling for missing documents during the audit. Using an electronic documentation management system like Document Compliance Network will keep all your supplier documents up to date for you. While you work on improving the food safety program, our software can be working behind the scenes to request missing and expiring documents from your suppliers. That way when the auditor asks for a product specification it is only a few clicks away.

- 51 Views

- 0 Comments

Recent Post

Daria Van De Grift

- 51 Views

- 0 Comments